Jun 8th 2020

How to Install DuraTech Chimney Systems

Simpson DuraTech is an all-fuel chimney system designed for appliances that require a UL 103 or a UL HT chimney system, such as wood stoves, fireplaces, furnaces, boilers, stoves, ranges, water heaters, or other appliances fueled by wood, oil, coal, or gas, and zero clearance fireplaces that are factory-built. With a Thermal Tech blanket insulation encased between dual walls, DuraTech offers the optimum in safety and performance. Inner wall .020" 430 stainless steel. Outer wall options of .016" 430 stainless steel or .021" galvalume steel. A ceramic refractory blanket insulation is encased between walls. Stainless steel end rings seal the pipe. It keeps the outer wall of the chimney cool, while ensuring high flue gas temperatures for optimum draft performance. No locking bands or mechanical fasteners required. DuraTech's sleek 1" wall design provides for easy installation, such as 5"-8" diameter pipe installation through 16" on-center rafters. A black finish is available in 6", 9", and 12" pipe lengths. DuraTech carries a limited-lifetime warranty.

2" clearance to combustibles.

Designed for normal, continuous operation at 1000 degrees F flue gas temperatures, DuraTech (5"-8" diameters) is subjected to rigorous and stringent HT requirements of the UL standard, including on hour at 1400 degrees F, plus three ten-minute chimney fire tests at 2100 degrees F.

DuraTech 10"-24" diameters is tested and listed for continuous operation at 1000 degrees F flue gas temperatures, one hour at 1400 degrees F, and three, ten-minute chimney fire tests at 1700 degrees F, in accordance with UL 103 test standards.

C-UL-us Listed to UL 103 HT and ULC-S604 (file #MH7399) (Stainless steel outer wall required for installation in Canada.

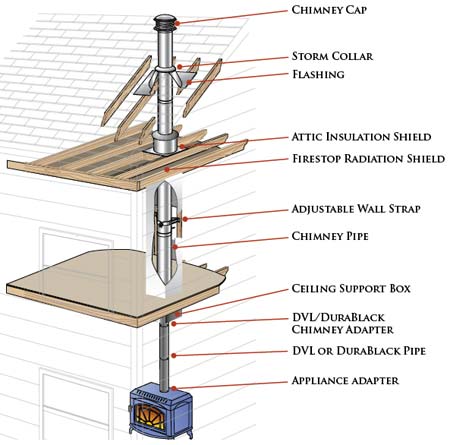

Typical Installations

Using the Typical Venting Installation drawings, select the appropriate component parts for your installation.

DVL/DuraBlack Chimney Adapter must be used when connecting DVL pipe to a ceiling support box or finishing collar. When connecting DuraBlack pipe, a DuraBlack Slip Connector or Snap-Lock Adapter must be used.

Wall Thimble must be installed with an appropriate length of chimney pipe for all horizontal through-the-wall installations. To accommodate thicker walls, the telescoping pieces can be separated, and a field-fabricated extension may be installed.

Attic Insulation Shield must be used in all installations that pass through an attic, regardless of the attic insulation.

Firestop Radiation Shield must be used when a chimney passes through a floor or ceiling without a support box.

Cathedral Ceiling

Oil Furnace

Attic Offset

Through The Wall

Fireplace (New or retrofit)

Installation Key

| Key: Installation Steps | |||

|---|---|---|---|

| 1 | DVL or DuraBlack | 11 | Tee with Tee Cap |

| 2 | Ceiling Support Box | 12 | Tee Support |

| 3 | Wall Thimble | 13 | Chase Top Flashing |

| 4 | Chimney Pipe | 14 | Base Tee/Double Tee |

| 5 | Attic Insulation Shield | 15 | Anchor Plate or Anchor Plate with Damper |

| 6 | Flashing | 16 | Roof Support |

| 7 | Storm Collar | 17 | Finishing Collar |

| 8 | Chimney Cap | 18 | DVL Adapter, DuraBlack Slip Connector, or Snap-Lock Adapter |

| 9 | Elbow | 19 | Stove Adapter |

| 10 | Elbow Strap | 20 | ... |

Be fire-safe! Maintain at least a minimum 2" clearance (air space) to combustibles. Use proper support and bracing. Follow local building codes and have your chimney inspected by a certified professional.